The popularity of 3d printing is growing across a variety of industries. The ability to print objects using a three-dimensional printer has many benefits, including reducing the amount of waste produced by traditional manufacturing methods. However, there are also some environmental challenges associated with 3d printing that needs to be addressed.

The need for the 3D Printing Industry to go green is a hot topic and a future advancement for technology. The industry is increasing, with new patents and businesses being created all the time. And with this growth comes an increased environmental impact.

From the materials used in 3d printers to the products printed, there are many ways that 3D printing technology can be more sustainable. However, before we jump into the solutions to achieve green 3d printing, let’s look at some barriers to it.

Barriers to Green 3D Printing

Below are the most critical challenges that companies and innovative 3D printing service startups need to consider and address:

1. Support Material Wastage:

When working with 3d printers, a lot of non-printed material is often used to support the 3D printed object being created. This support material needs to be removed from the finished product, wasteful and time-consuming. In addition, the removal process can be complex and cause damage to the finished product.

2. Incorrect Material Usage:

One of the competitive edges of additive manufacturing is that it allows for a wide range of materials to be used, including both traditional and non-traditional materials. However, not all of these materials are environmentally friendly. For example, some 3d printers use metals and plastics that can release toxins when melted down. Moreover, using multiple materials can also lead to waste and inefficiency.

3. High Energy Consumption:

3d printers are power-intensive devices, and the larger the object being printed, the more energy it consumes. A sizable 3d printer can consume as much power as a small refrigerator. This high energy usage creates an environmental burden and can be a barrier to the broader adoption of 3d printing.

4. Limited Recycling Options:

Currently, there is minimal recycling infrastructure for 3d printing products and materials. It means that most of the waste produced by 3d printing ends up in landfills. And since many of the materials used in 3d printers are not biodegradable, this waste can be harmful to the environment.

5. Use Of Hazardous Materials:

Some 3d printing materials, such as plastics and metal powders, can be harmful if not handled correctly. In particular, plastics in 3d printing can release toxic fumes and particles into the air. These pollutants can harm both human health and the environment.

Ways To Make 3D Printing Solutions More Eco-Friendly

There are multiple efficient ways that a company can use 3D print objects in an eco-friendly manner. Some of the essential methods are:

1. Use Biodegradable Materials:

Several biodegradable materials are available for 3d printing, including plant-based polymers, natural fibers, and biopolymers. These materials break down easily and do not release harmful pollutants into the environment. In addition, they are renewable and sustainable, making them a more environmentally friendly option than traditional plastics.

2. Improve Material Usage:

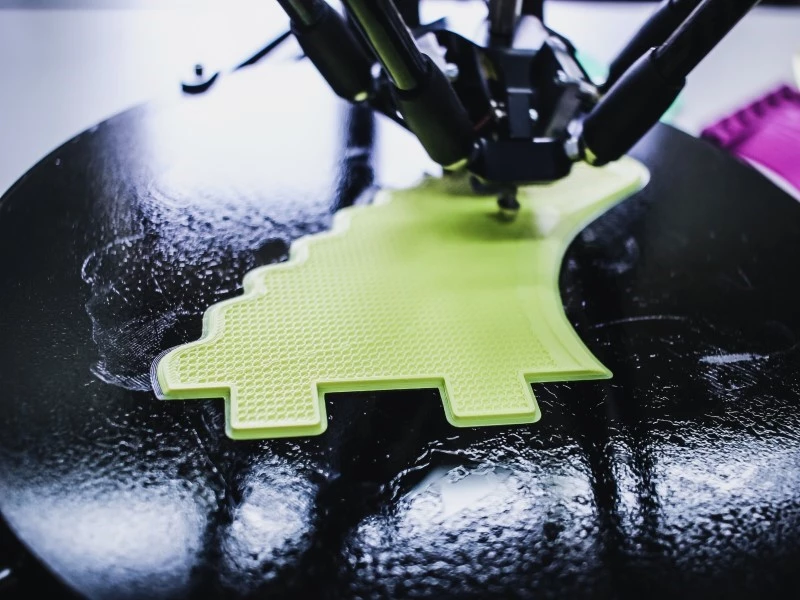

By using the correct amount of material for each print job, companies can reduce waste and save on resources. In addition, optimizing the 3d model for printing can also help minimize material usage. For example, using a lattice or honeycomb structure can reduce the material needed for support.

3. Use Energy-Efficient Printers:

There are many energy-efficient 3d printers available on the market. These printers use less power and produce less waste heat than traditional 3d printers. In addition, they often have smaller footprints, making them more space-efficient.

In addition, one of the simplest ways to make 3d printing more sustainable is to promote recycling. There are already a few recycle programs for 3d printing products and materials, but more need to be created.

4. Building An Enclosure 3D Printers:

An enclosure can be built around the 3D printer to help control the environment. This advancement includes a filter to remove harmful fumes and particles from the air and a heated chamber to prevent the material from cooling down too quickly. By enclosing the printer, companies can improve the quality of the printing process and reduce the environmental impact.

5. Using A Filament Recycler:

A filament recycler is ideal for recycling 3d printer filament from waste materials. It not only reduces waste but also saves on the cost of filament. In addition, using recycled filament can help reduce the environmental impact of 3d printing. In addition, it allows companies to save on the cost of filament.

6. Eliminate Unnecessary Inventory:

Companies need to adopt a print-on-demand model, which would help reduce the wastage of resources by eliminating unnecessary inventory. Several companies heavily store products that might not be in demand for years, leading to an increase in environmental hazards and carbon emissions. Thus, 3D printing can help these companies to reduce the wastage of resources and focus on a “just in time” philosophy.

Future Of Green 3D Printing

The future of green 3d printing looks promising. With the increase in awareness of the need to be more sustainable, more companies are looking for ways to make 3d printing more environmentally friendly. In addition, researchers are continually working on new and improved ways to make 3d printing more sustainable. Thus, the future of green 3d printing looks bright and promising.

By using biodegradable materials and changing their approach to manufacturing items, companies can reduce the environmental impact of 3d printing. In addition, by using recycled materials and energy-efficient printers, companies can make 3d printing more sustainable.

Final Words

There are several ways to make its 3d printing solutions more environmentally friendly. With the growing popularity of additive manufacturing (AM), we will see more efficient and eco-friendly 3d printers hit the market. So, companies need to switch to more sustainable printing methods. In addition, professional training to design optimized 3d models for printing can help reduce material usage, saving money and resources. By making these small adjustments, we can help create 3D printing more sustainable for the future.

Spread the love